Vibrations permeate our world, from the thunderous roar of machinery to the gentle sway of a melody. While acoustic vibrations primarily affect our auditory perception, structural vibrations can have broader implications, influencing the stability, performance, and safety of mechanical systems and structures. Controlling these structural vibrations is a critical challenge faced by engineers and researchers alike.

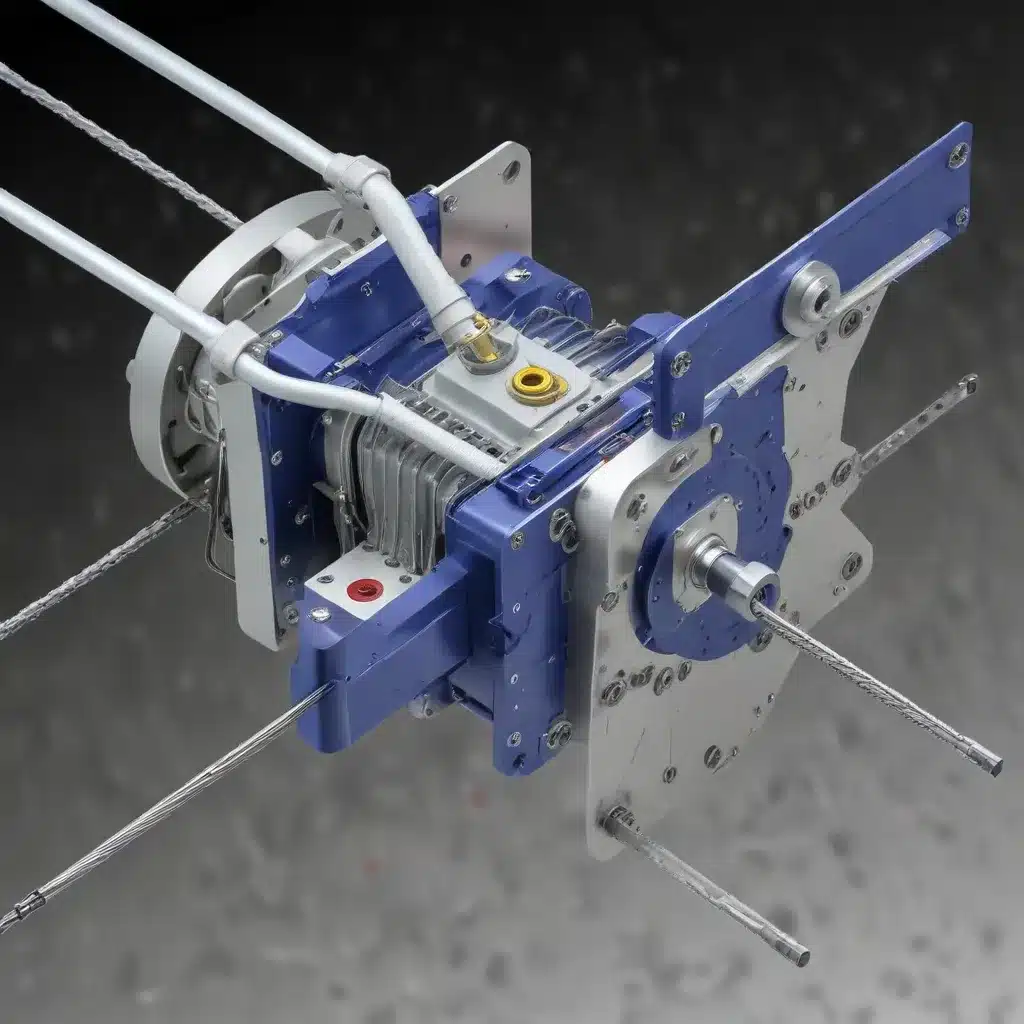

Granular Damping Systems

One promising approach to mitigate the effects of structural vibrations involves the use of granular materials—collections of discrete, solid particles that interact through contact forces. Dr. Igor Emri, Dr. Simon Oman, and their colleagues at the University of Ljubljana in Slovenia have pioneered an innovative technology that harnesses the unique properties of granular materials to achieve exceptional vibration damping performance.

The key to this technology lies in the interplay between two energy dissipation mechanisms that operate at different scales within the granular material. At the molecular scale, interactions between the polymer molecules are regulated by the pressure-frequency superposition principle, which states that changes in the frequency or rate of energy application have effects equivalent to changes in temperature. At the macroscale, the rearrangement of granules in response to external forces leads to the formation of force chains that efficiently transmit and dissipate the applied energy.

The researchers have developed Granular Damping Elements (GDEs) that leverage these complementary mechanisms to achieve vibration damping performance up to 100 times higher than conventional polymeric materials. The secret lies in the carefully engineered granular structure, which allows the material to exhibit both high damping capacity and mechanical stability.

Composition and Structure

The GDEs are composed of thermoplastic polyurethane (TPU) granules, which combine the flexibility and elasticity of rubber with the ability to retain their chemical structure even after repeated melting and solidification. By tuning the size, shape, and distribution of the granules, the researchers can optimize the material’s flowability, enabling the granules to rearrange and form stable force chains under dynamic loading conditions.

Damping Principles

The vibration-damping properties of the GDEs are attributed to the two complementary energy dissipation mechanisms. At low levels of prestress, the macroscale force-chain network mechanism dominates, as the granules rearrange to efficiently transmit and dissipate the applied forces. As the prestress increases, the molecular-scale, pressure-dependent dissipation within the granules becomes more prominent, further enhancing the damping performance.

Applications and Effectiveness

The GDE technology offers a versatile and highly effective solution for vibration mitigation across a wide range of industries, including transportation, aerospace, and energy. By tailoring the material composition and processing parameters, the researchers can optimize the GDEs for specific applications, targeting both vibration damping and structural support functions.

Experimental studies have demonstrated that the GDEs can provide up to four times better vibration-damping performance compared to the same material in bulk form. This breakthrough has significant implications for the development of lightweight, high-performance vibration-damping systems that can enhance comfort, safety, and the overall performance of mechanical systems.

Force-Network Modeling

The theoretical and practical success of the GDE technology is underpinned by the researchers’ in-depth understanding of the underlying principles governing the behavior of granular materials under dynamic loading conditions.

Theoretical Foundations

The high-pressure force-network technology developed by Emri and his team builds on the principles of the Knauss-Emri model, a pioneering approach to studying the nonlinear behavior of time-dependent materials. This model accounts for the simultaneous effects of temperature and pressure on the mechanical properties of polymers, providing a framework for predicting the material’s response to various loading conditions.

Numerical Simulations

To further elucidate the complex interactions within the granular system, the researchers have employed advanced numerical modeling techniques. By simulating the formation and evolution of the force-chain network, they have gained valuable insights into the mechanisms governing the material’s vibration-damping capabilities.

Experimental Validation

The theoretical and computational work has been meticulously validated through extensive experimental investigations. The researchers have developed specialized testing equipment, such as the Granular Friction Analyzer, to characterize the flowability and internal stress distributions within the granular material under various loading conditions.

Novel Damping Mechanisms

The unique properties of the GDE technology emerge from the interplay between the granular material’s microstructure and the underlying energy dissipation pathways.

Granular Media Interactions

The researchers have discovered that the granular structure of the TPU material plays a crucial role in enhancing the vibration-damping performance. By creating a multimodal size distribution of the granules, they have been able to optimize the flowability of the material, enabling the formation of a stable force-chain network under dynamic loading.

Energy Dissipation Pathways

The two complementary energy dissipation mechanisms—molecular-scale interactions and macroscale force-chain rearrangements—work in tandem to provide exceptional vibration-damping capabilities. The precise tuning of these mechanisms, through material selection and processing parameters, is the key to unlocking the full potential of the GDE technology.

Optimization Strategies

Ongoing research efforts focus on further optimizing the GDE technology, exploring the effects of various granule parameters, such as shape, size, and initial prestress, on the overall damping performance. By leveraging these insights, the researchers aim to develop tailored solutions for specific applications, ensuring the best balance between vibration-damping, structural support, and weight reduction.

Performance Evaluation

To quantify the effectiveness of the GDE technology, the researchers have developed a new design-oriented performance metric that considers both the vibration-damping capabilities and the weight-to-stiffness ratio of the material.

Vibration Attenuation Metrics

The design parameter (ηD) introduced by the team combines the material’s specific damping capacity with its stiffness and mass, providing a comprehensive assessment of the vibration-damping performance in the context of practical engineering applications.

Parametric Sensitivity Analysis

The experimental results have revealed the critical role of various factors, such as the level of prestress, material composition, and the use of lubricants, in optimizing the damping performance of the GDEs. The researchers have systematically explored the sensitivity of the technology to these parameters, guiding the further development and refinement of the GDE solutions.

Comparative Assessments

When compared to conventional vibration-damping materials and technologies, the GDE system has demonstrated its superior performance, with up to four times better vibration-damping capabilities than the bulk TPU material. This breakthrough paves the way for the adoption of the GDE technology in a wide range of industries, where the demand for lightweight, high-performance vibration-damping solutions is ever-increasing.

The pioneering work of Dr. Emri, Dr. Oman, and their team at the University of Ljubljana has unveiled a new frontier in vibration mitigation. By harnessing the unique properties of granular materials, the GDE technology offers a versatile and highly effective solution for enhancing the comfort, safety, and performance of mechanical systems across diverse industries. As the world continues to seek innovative approaches to address the challenges of vibration, this groundbreaking research holds the promise of a more vibrant, resilient, and sustainable future.